Cobots

Cobots Alpha Coding

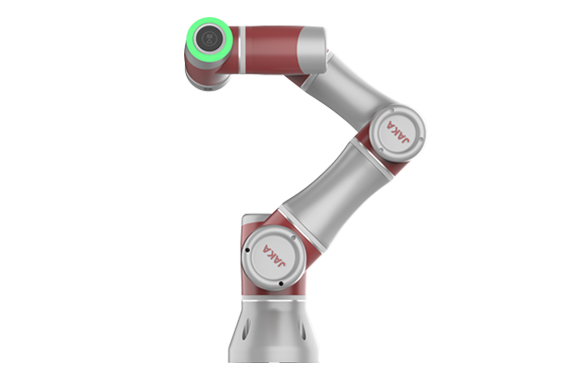

Alpha coding brings you the ultimate solution for batch coding and label marking. All our products range from manual to automatic and variety of types of quality products from well-known brands, can take your batch coding task to an upper level. These days we are facing challenge producing and labeling products for huge consumers. To solve that problem cobot or collaborative robot is introduced which is much more efficient and optimizable than human. It is designed to help you to make automate operations in your industry. The cobot is an automatic robot designed in a way so that it can work in an environment where humans also operate ensuring their safety and physical integrity. The cobot can easily interact with the operator and perform repetitive, low-value-added tasks that includes positioning or moving parts. The simplified interface of cobot makes it easily programmable and able to manipulate it directly. Some types of cobot comes with gripping action of the human hand and manipulate objects of different size, shape and weight with a single clamp and ready to meet the needs of different production situation.

KEY BENEFITS OF COBOTS

- They do not require a protective cage and therefore simplify the production line and the movement of operators

- Versatility and flexibility

- They reduce performance losses and non-qualities related to operator fatigue

- They value the operator on tasks with higher added value

- In general, they increase the attractiveness of the operator position

Unlike traditional industrial robots, cobots are free of industrial injury risk. Nowadays, we frequently face the problems of constantly increasing labor costs and shortening product market life cycle. Where these cobots have all the advantages of advanced robotics and automation technology and thankfully free of costs of programming at the same time. These robots also don’t need startup settings and safety protection settings which are necessary for traditional robots and thus freeing people from unnecessary task.

These cobots are equipped with advanced industrial force sensor, and integrated with force control algorithm of independent intellectual property rights that can satisfactorily improve the perception of cobots and provide better man-machine interaction experience as well as security guarantee for customers. Cobot comes with a variety of force control solutions such as constant force, normal tracking and speed mode to realize full-arm collision detection. Basic Parameter Hardware Platform Force sensor, Maximum accuracy of collision detection communication interface are the most convenient feature of cobot.

A collaborative robot can free up 2 to 3 operators from the most repetitive tasks;

The cobot operates 24/7, which improves the efficiency of the production line and increases production. The JAKA Zu series can make a flexible grip and 360-degree rotational treatment to ensure the stability of the product process.With the JAKA Zu series loading and unloading are fully automatic, guaranteeing the quality and efficiency of production.

Our available cobot models

Jaka Zu 3s up to 3 kgs payload, Jaka Zu 5s up to 5kgs payload, Jaka Zu 7s up to 7 kgs payload, Jaka Zu 12s up to 12 kgs payload and Jaka Zu 18s up to 18 kgs payload. We provide proper guidance and product shipment service. We are more than happy to assist you in any situation, in any matter.